Have you ever thought about growing your own sprouts in bulk? Well, look no further because this article is here to guide you through the process. Discover the benefits of sprout production on a larger scale, from saving money to having a fresh supply of nutritious sprouts at your fingertips. Whether you’re a seasoned gardener or a beginner in the world of plant cultivation, this comprehensive guide will provide the knowledge and tips you need to successfully grow your own sprouts in large quantities. Get ready to embark on an exciting journey into the world of sprout production!

Choosing Sprout Varieties

Understanding Different Types of Sprouts

When it comes to sprout production, it’s important to have a good understanding of the different types of sprouts available. There are various varieties to choose from, including alfalfa, mung bean, broccoli, radish, and many more. Each type of sprout has its own unique flavor and texture profile, so it’s important to consider your personal preferences as well as the preferences of your potential customers. Some sprouts have a milder flavor, while others are more peppery or nutty. Experimenting with different types of sprouts can help you diversify your product offerings and cater to a wider consumer base.

Considering Flavor and Texture

When selecting sprout varieties for bulk production, it’s crucial to consider the flavor and texture of the sprout. The flavor of sprouts can range from mild and delicate to strong and pungent. The texture can be crisp, crunchy, or tender. It’s important to choose sprout varieties that will appeal to your target market. Conducting taste tests and gathering feedback from potential consumers can give you valuable insights into which sprouts are most popular and preferred. Remember, a good balance of different flavors and textures can be appealing to a wider range of customers.

Selecting Sprouts for Bulk Production

When producing sprouts in bulk, it’s essential to select varieties that are suitable for large-scale cultivation. Some sprout varieties are more prolific than others, meaning they yield a greater quantity of sprouts per seed or legume. Additionally, consider the growth rate of the sprout varieties you choose. Some sprouts mature and are ready for harvest faster than others, which can impact your production schedule. It’s important to strike a balance between sprout quality, yield, and production efficiency to ensure a successful and profitable operation.

Setting Up the Sprouting Area

Choosing a Suitable Location

The location of your sprouting area plays a crucial role in the success of your sprout production. Choosing a suitable location involves considering factors such as temperature, humidity, accessibility, and contamination risks. Ideally, the sprouting area should be in a clean, well-ventilated room with a controlled temperature and humidity level. It should also be easily accessible for regular maintenance, monitoring, and harvesting.

Creating an Ideal Environment

Creating an ideal environment for sprouting involves ensuring the right temperature, humidity, and lighting conditions. Most sprouts thrive in temperatures between 60°F and 75°F (15°C to 24°C), with a humidity level of around 70%. You may need to invest in thermostats, humidifiers, and ventilation systems to maintain the ideal conditions. Adequate lighting is also important, as sprouts need some exposure to light for optimal growth. Natural light or artificial lighting systems can be utilized based on the availability and practicality of your setup.

Ensuring Proper Ventilation

Ventilation is a critical aspect of sprout production as it helps prevent the growth of mold, bacteria, and other pathogens. Good airflow is essential to maintain optimal air quality and prevent excessive moisture buildup, which can lead to contamination. Consider installing fans or air vents in your sprouting area to facilitate proper air circulation. Regularly clean and maintain the ventilation systems to prevent the accumulation of dust and debris.

Organizing Equipment and Supplies

Efficient organization of equipment and supplies ensures smooth operations and reduces the risk of contamination. Consider setting up designated areas for soaking, sprouting, rinsing, and packaging processes. Keep all equipment clean, properly sanitized, and easily accessible. Store seeds, legumes, and other supplies in a dedicated area, preferably in sealed containers to maintain freshness and prevent cross-contamination. Regularly check and restock your inventory to prevent any disruptions to your production process.

Selecting Quality Seeds or Legumes

Recognizing the Importance of Seed Selection

Selecting high-quality seeds or legumes is crucial for successful sprout production. Look for suppliers that provide reliable and certified seeds specifically meant for sprouting. High-quality seeds have a higher germination rate, ensuring a greater yield of healthy sprouts. Investing in reputable seed suppliers can contribute to the overall quality and safety of your sprout production.

Choosing Organic and Non-GMO Options

In today’s health-conscious market, many consumers prefer organic and non-GMO options. Choosing organic and non-GMO seeds or legumes can help meet the demands of this growing consumer base. Organic sprouts are grown without the use of chemical fertilizers or pesticides, while non-GMO sprouts are free from genetically modified organisms. Opting for these seeds not only aligns with consumer preferences but also promotes sustainable and environmentally-friendly practices.

Checking for Freshness and Viability

Before purchasing seeds or legumes, it’s important to check for freshness and viability. Fresh seeds have a higher chance of germination and yield healthier sprouts. Look for suppliers who provide seeds with a recent production date. Conducting germination tests on a small sample of seeds can also help ensure their viability. This involves soaking and sprouting a small number of seeds to see if they successfully germinate. If a high percentage of seeds sprout, it indicates good seed quality.

Preparing Sprouting Containers

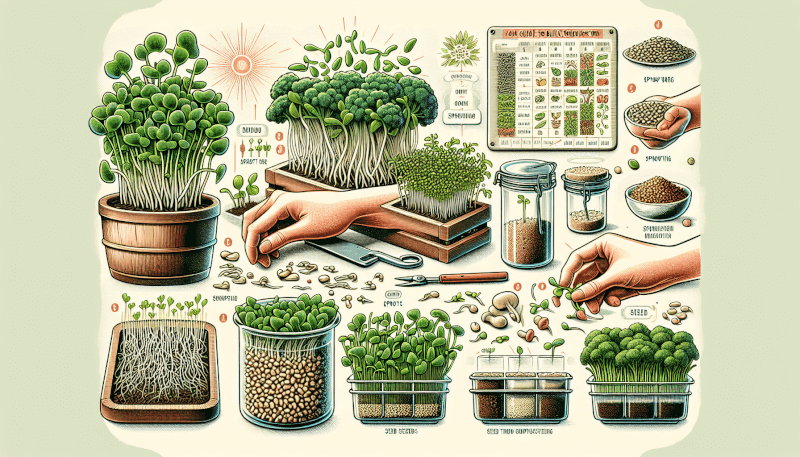

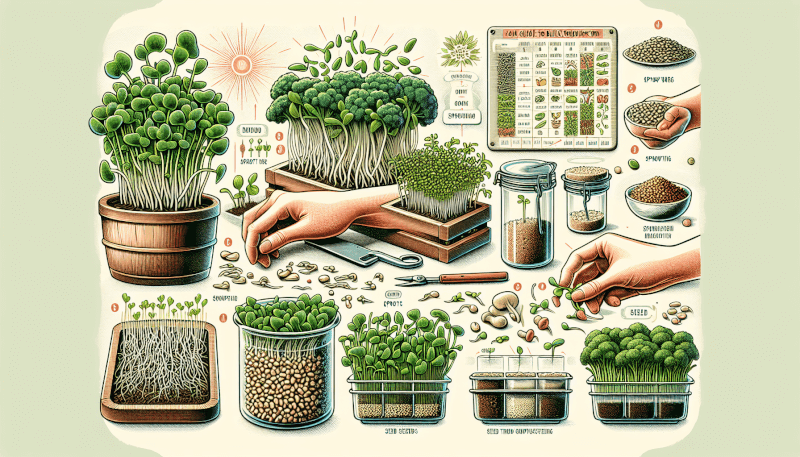

Deciding on Container Types

When preparing sprouting containers, you have several options to choose from. Popular container types include glass jars, sprouting trays, and specialized sprouting containers. Each type has its advantages and considerations. Glass jars are readily available and allow you to see the sprouting progress, while sprouting trays maximize space efficiency. Specialized sprouting containers often offer features like built-in drainage systems. Consider the scale of your production, the type of sprout, and personal preferences when deciding on the container types.

Properly Cleaning and Sterilizing Containers

Maintaining a clean and sterile sprouting environment is crucial to prevent the growth of harmful bacteria and pathogens. Before using any sprouting containers, they should be thoroughly cleaned and sterilized. Wash containers with hot soapy water, rinse them thoroughly, and then use a food-grade sanitizer to ensure complete sterilization. Regularly inspect and replace containers that show signs of wear and tear or damage to maintain optimal hygiene standards.

Creating Drainage Systems

Proper drainage is essential to prevent waterlogging, which can lead to the formation of mold or rot in your sprouts. Depending on the container type, you may need to create or optimize the drainage system. For example, in glass jars, you can use mesh screens or cheesecloths secured with rubber bands to cover the jar openings, allowing for easy drainage of excess water. Sprouting trays often have built-in drainage systems, making them convenient for larger-scale production. Ensure that the drainage system is effective and allows water to flow freely without stagnating.

Optimizing Space and Placement

Efficient use of space is important when setting up your sprouting area, especially in bulk production. Arrange your sprouting containers in a way that maximizes space without compromising ventilation and access for maintenance. Utilize shelves, racks, or stackable containers to optimize vertical space. Ensure that there is adequate space between containers to allow air circulation and avoid cross-contamination. Consider the workflow and accessibility when arranging containers to streamline your production process.

Soaking and Rinsing Process

Understanding the Importance of Soaking

Soaking is a crucial step in the sprouting process as it rehydrates the seeds or legumes and initiates the germination process. Soaking softens the seed coat, allowing for easier sprouting and faster growth. It also helps remove any natural inhibitors that may prevent germination. The duration of soaking varies depending on the type of seed or legume, but generally ranges from a few hours to overnight. Proper soaking is essential for ensuring optimal sprout development.

Determining Optimal Soaking Time

To determine the optimal soaking time, refer to the specific instructions provided by your seed or legume supplier. If such instructions are not available, you can experiment with different soaking times to find the ideal duration for each type of sprout. Keep in mind that over-soaking can lead to waterlogged or mushy sprouts, while under-soaking may result in slower or uneven germination. Regularly monitor the soaking process and adjust the soaking time as needed based on the results.

Rinsing Techniques and Frequency

Rinsing plays a crucial role in maintaining a clean and healthy sprouting environment. It helps remove any residual seed coatings, prevent bacterial growth, and refreshes the sprouts with clean water. The frequency of rinsing depends on the sprout variety and the environmental conditions. Generally, rinsing twice a day is recommended for most sprouts. Use gentle rinsing techniques, such as running water or the misting function on a spray bottle, to avoid damaging the delicate sprouts.

Using Quality Water and Rinse Solutions

Using quality water is essential for sprout production. Ideally, use filtered or purified water to minimize the risk of contamination from chemicals or impurities. Avoid using chlorinated water, as it can inhibit the growth of sprouts. If necessary, let tap water sit for a few hours to allow the chlorine to dissipate before using it for rinsing. Some sprout growers also use rinse solutions, such as diluted hydrogen peroxide or apple cider vinegar, to further enhance cleanliness and inhibit bacterial growth. However, it’s important to use these solutions in appropriate concentrations to prevent any negative effects on the sprouts.

Sprouting Techniques

Choosing a Sprouting Method

There are several sprouting methods to choose from, including jar sprouting, tray sprouting, and bag sprouting. Each method has its own advantages and considerations. Jar sprouting is simple and suitable for small-scale production. Tray sprouting allows for large-scale production and efficient use of space. Bag sprouting is convenient for on-the-go sprouting or when space is limited. Consider factors such as the scale of your operation, available equipment, and personal preferences when selecting a sprouting method.

Understanding Different Sprouting Techniques

Different sprout varieties require different sprouting techniques to optimize their growth and development. Some sprouts, like alfalfa and clover, are typically sprouted in jars or trays with a mix of soaking and rinsing. Others, like mung beans, are often sprouted using bag or tray sprouting methods. Research and understand the specific sprouting techniques recommended for each sprout variety you choose. Experimentation and experience will help you refine your techniques and achieve consistent and high-quality sprout production.

Managing Sprouting Parameters

Managing sprouting parameters refers to monitoring and controlling factors such as temperature, humidity, and airflow during the sprouting process. Each sprout variety has different optimal conditions for sprouting. It’s important to track and adjust these parameters accordingly to ensure optimal growth and avoid issues like mold or bacterial contamination. Use thermometers, humidity monitors, and airflow meters to accurately assess and manage the sprouting environment. Regularly monitor and record the sprouting parameters to identify patterns and make necessary adjustments for better control.

Avoiding Common Sprouting Issues

Sprouting can be a finicky process, and various issues may arise during production. Common sprouting issues include mold growth, bacterial contamination, uneven sprouting, and slow or stunted growth. By maintaining proper hygiene practices, following recommended sprouting techniques, and monitoring the sprouting environment, you can minimize these issues. Regularly inspect sprouts for any signs of discoloration, off odors, or abnormal growth patterns. Immediately address and rectify any issues to prevent them from spreading and affecting the entire batch.

Monitoring and Troubleshooting

Establishing a Monitoring Schedule

Regular monitoring is crucial to ensure the health and quality of your sprouts. Establish a monitoring schedule to regularly assess various factors such as temperature, humidity, airflow, seed germination rates, and signs of contamination. Monitor these parameters multiple times a day, especially during critical phases of the sprouting process like soaking, germination, and rinsing. A well-established monitoring schedule ensures early detection of any issues or deviations from the desired conditions, allowing for timely interventions.

Recognizing Signs of Healthy Sprouts

Healthy sprouts exhibit certain characteristics that indicate their quality and viability. Look for traits like vibrant green color, crisp texture, and a fresh, mild aroma. Healthy sprouts should have even growth across the batch, without any signs of discoloration, mold, or rot. Taste testing can also help verify the quality and flavor of the sprouts. Familiarize yourself with the expected appearance, texture, and smell of each sprout variety to recognize any deviations that may indicate potential issues.

Identifying and Addressing Common Issues

Despite careful monitoring and adherence to best practices, sprouting issues may still arise. It’s important to promptly identify and address these issues to prevent further contamination or quality degradation. Common issues include mold growth, foul odors, excessive moisture, or uneven sprouting. If you encounter such issues, assess the potential causes, such as improper hygiene practices, insufficient rinsing, or inadequate ventilation. Take immediate corrective actions, such as adjusting environmental conditions, boosting hygiene practices, or disposing of affected batches to prevent the issues from recurring.

Dealing with Contamination

Contamination is a serious concern in sprout production as it can compromise the safety and quality of the sprouts. Contaminants can include harmful bacteria, mold, yeast, or even chemical residues. To prevent contamination, prioritize hygiene practices, including cleaning and sanitizing equipment regularly. Isolate and dispose of contaminated batches immediately to prevent the spread of contaminants. Implement proper disinfection protocols and consider periodic testing of your sprouts for microbial safety to ensure compliance with regulatory requirements.

Harvesting and Storing Sprouts

Determining Optimal Harvest Time

Harvesting sprouts at the optimal time ensures the best flavor, texture, and nutritional content. The exact harvest time can vary depending on the sprout variety and personal preferences. Generally, sprouts are ready for harvest when they have reached their desired length, have open leaves or cotyledons, and have shed their seed coats. Taste testing can help determine the final flavor and texture of the sprouts. Regularly monitor the sprouting progress and adjust the harvest time based on your desired quality standards.

Harvesting Techniques

When harvesting sprouts, gentle handling is important to prevent damage or bruising. Depending on the container type, harvesting techniques may vary. For jar sprouting, carefully pour out the sprouts into a colander or strainer, separating them from any remaining seed coats. For tray or bag sprouting, gently remove the sprouts from the trays or bags, ensuring minimal disturbance to the delicate roots. Avoid excessive handling or rough shaking, as it can cause damage or bruising. Clean and sanitize any harvesting equipment to maintain hygiene standards.

Properly Cleaning and Drying Sprouts

After harvesting, it’s important to clean and dry the sprouts properly before packaging or consuming. Thoroughly rinse the sprouts in clean, filtered water, gently agitating them to remove any debris or loose seed coats. Allow the sprouts to drain completely, ensuring excess water is removed. Depending on the sprout variety, you may also gently pat them dry with clean paper towels or use a salad spinner to remove excess moisture. Proper cleaning and drying ensure a fresh and crisp final product.

Storage Recommendations and Shelf Life

To prolong the shelf life and maintain the quality of your sprouts, proper storage is crucial. Store the cleaned and dried sprouts in sealed containers in the refrigerator at a temperature between 34°F and 38°F (1°C to 3°C). Keeping the sprouts in airtight containers helps prevent moisture loss and contamination. Check the sprouts regularly for any signs of spoilage, discoloration, or off odors. The shelf life of sprouts can vary depending on the variety, but generally ranges from 5 to 7 days when stored properly.

Maintaining Proper Hygiene

Importance of Hygiene in Sprout Production

Maintaining proper hygiene is of utmost importance in sprout production to ensure the safety and quality of your sprouts. Contaminants can quickly multiply and spread in the warm and moist environment that sprouting provides. Implementing stringent hygiene practices minimizes the risk of contamination and helps meet regulatory requirements. Prioritize regular cleaning and sanitizing of equipment, practicing good personal hygiene, and adhering to industry-standard hygiene procedures to establish a robust food safety system.

Cleaning and Sanitizing Equipment

Regular cleaning and sanitizing of equipment are essential to prevent cross-contamination and the growth of harmful bacteria. Develop a cleaning schedule that includes routine cleaning after each batch, as well as more thorough sanitization on a regular basis. Use food-grade sanitizers and detergents to properly clean and disinfect sprouting containers, trays, screens, and other equipment. Pay special attention to areas that come into direct contact with sprouts to ensure complete removal of any potential contaminants.

Personal Hygiene and Safety Measures

Personal hygiene practices are equally important in sprout production. Establish strict protocols for employees, emphasizing proper handwashing techniques, wearing clean and appropriate attire, and avoiding direct contact with sprouts. Ensure that employees are trained in food safety practices and understand the importance of personal hygiene in preventing the spread of contaminants. Implement regular health checks for employees to minimize the risk of any potential illness affecting the sprout production.

Developing and Implementing Good Manufacturing Practices

Developing and implementing Good Manufacturing Practices (GMP) is crucial for maintaining high standards of hygiene and safety in sprout production. GMP guidelines provide a framework for managing the overall operations, hygiene practices, and quality control in sprout production. Consider factors such as facility design, employee training, sanitation procedures, and record-keeping systems when developing your GMP protocols. Regularly assess and update your GMP practices to ensure ongoing compliance with regulatory requirements and industry standards.

Scaling Up Production

Expanding Sprout Production Capacity

If you’re considering scaling up your sprout production, proper planning and preparation are essential. Evaluate your current production capacity and determine the level of expansion required. This may involve investing in additional equipment, increasing production space, or hiring additional staff. Conduct a cost analysis to assess the financial feasibility of scaling up your operation. Consider market demand, competition, and potential growth opportunities to ensure a sustainable and profitable venture.

Managing Increased Workload

Scaling up production inevitably means managing a larger workload. Proper workforce planning and task delegation are crucial to ensure efficiency and productivity. Assess the existing skills and capabilities of your team and identify areas that need additional support or training. Develop clear work schedules and standard operating procedures (SOPs) to streamline the production process and minimize bottlenecks. Regularly assess and evaluate the workload distribution to ensure a balanced and manageable operation.

Scaling Equipment and Supplies

As you scale up your sprout production, it’s important to assess and upgrade your equipment and supplies accordingly. This may involve investing in larger sprouting trays, more spacious storage solutions, or automated equipment to increase efficiency. Ensure that your suppliers can meet the demand for seeds or legumes in larger quantities without compromising quality. Regularly reassess your equipment and supply needs to ensure that they align with the production scale and growth projections of your operation.

Ensuring Consistency in Larger Batches

Maintaining consistency in the quality and characteristics of your sprouts becomes even more critical as you produce larger batches. Implementing standard operating procedures (SOPs) and ensuring thorough training for your team can help achieve consistency. Regularly monitor and assess the sprouting parameters, hygiene practices, and production processes to ensure they align with your desired standards. Conduct quality control checks and taste tests for every batch to ensure that the sprouts meet the expected quality in taste, texture, and appearance.

In conclusion, successful bulk sprout production requires careful consideration and attention to various factors at each stage of the process. From choosing the right sprout varieties to maintaining proper hygiene and scaling up your production, every aspect plays a crucial role in ensuring the quality, safety, and profitability of your sprout business. By following best practices, staying vigilant, and continuously improving your techniques, you can cultivate a thriving sprout production operation and provide fresh, nutritious sprouts to your customers.